Hot forging is a manufacturing process that involves shaping metals above their recrystallization temperature. During hot forging, the material is heated to a temperature where it becomes malleable and ductile, allowing it to be shaped into complex 3D geometries.

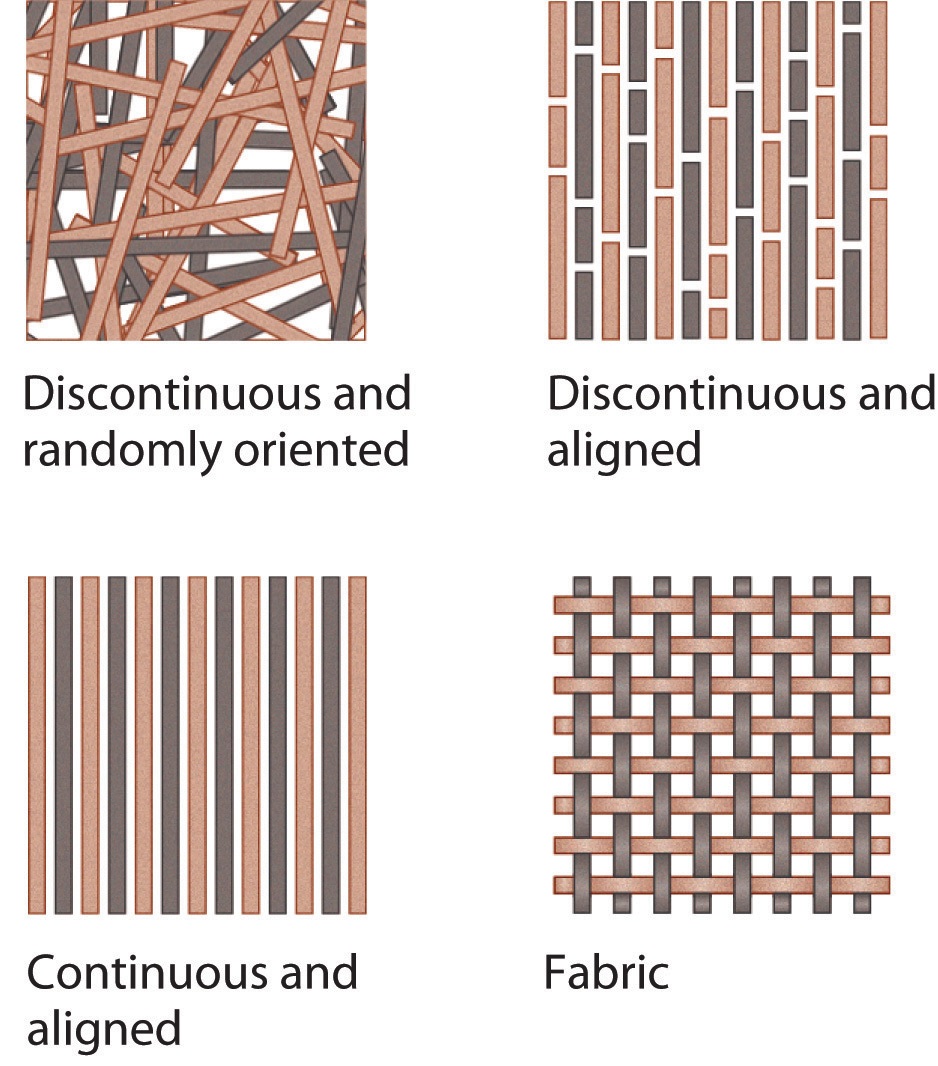

Hot forging is used for materials that are difficult to form at room temperature, such as high-strength alloys, which can be formed only with limitations when cold. The higher temperatures used in hot forging make these materials more malleable, allowing them to be formed into complex shapes without cracking or breaking.

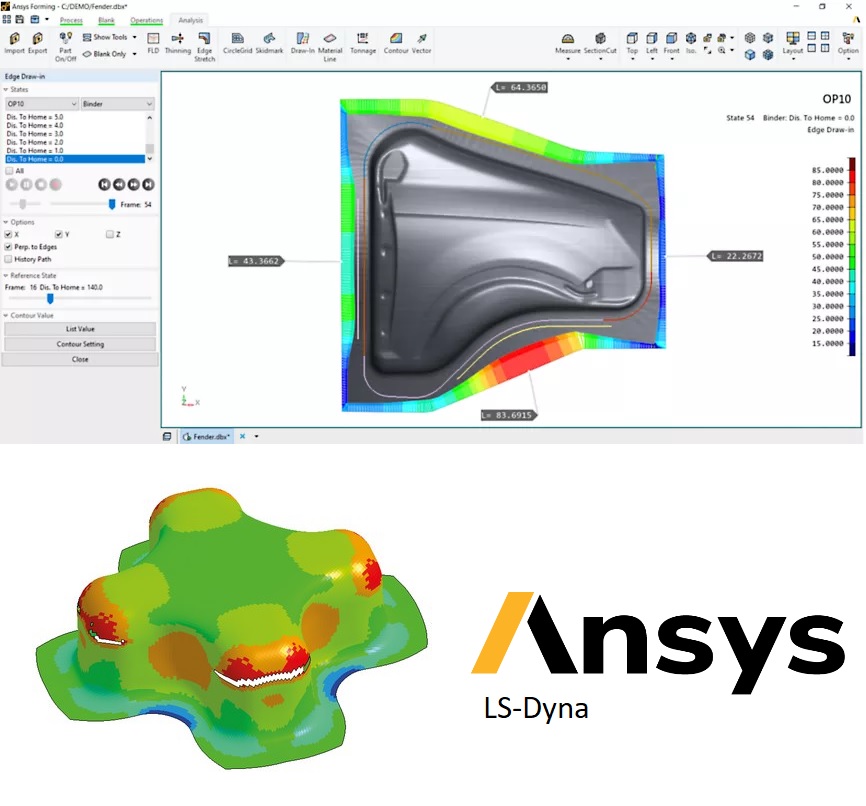

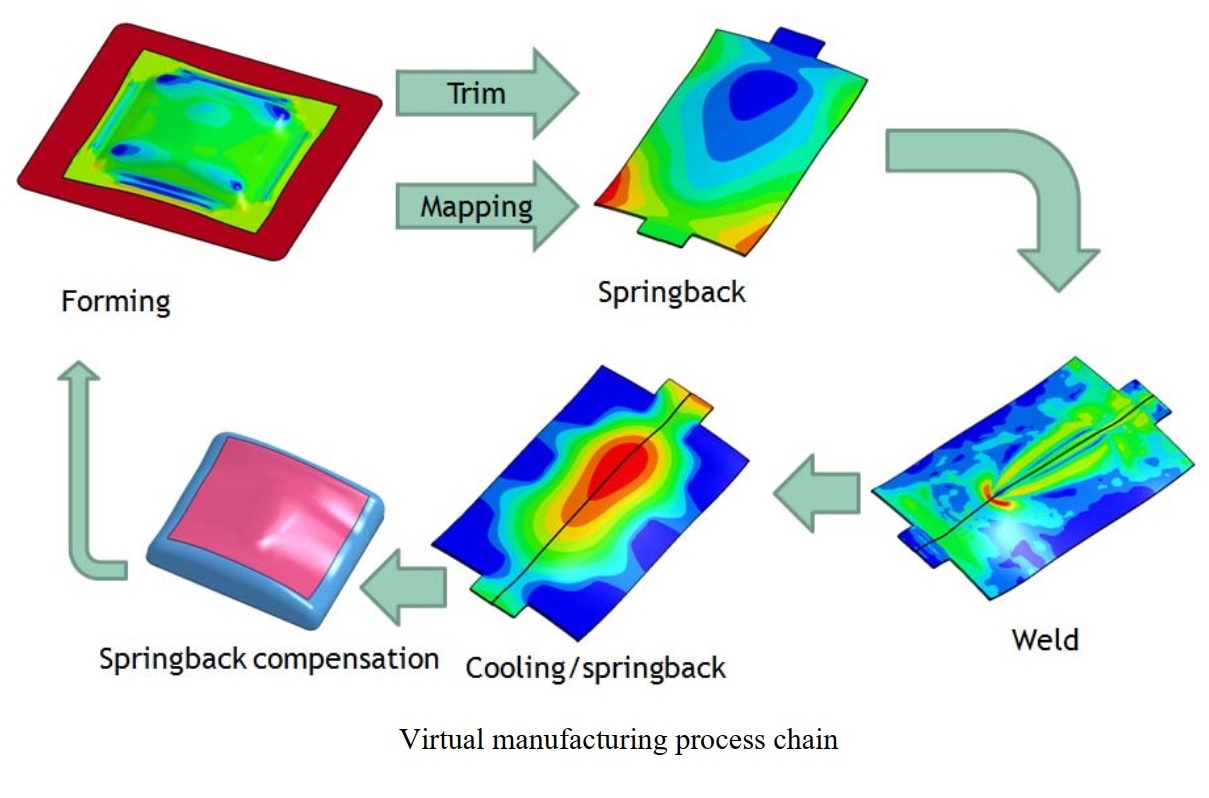

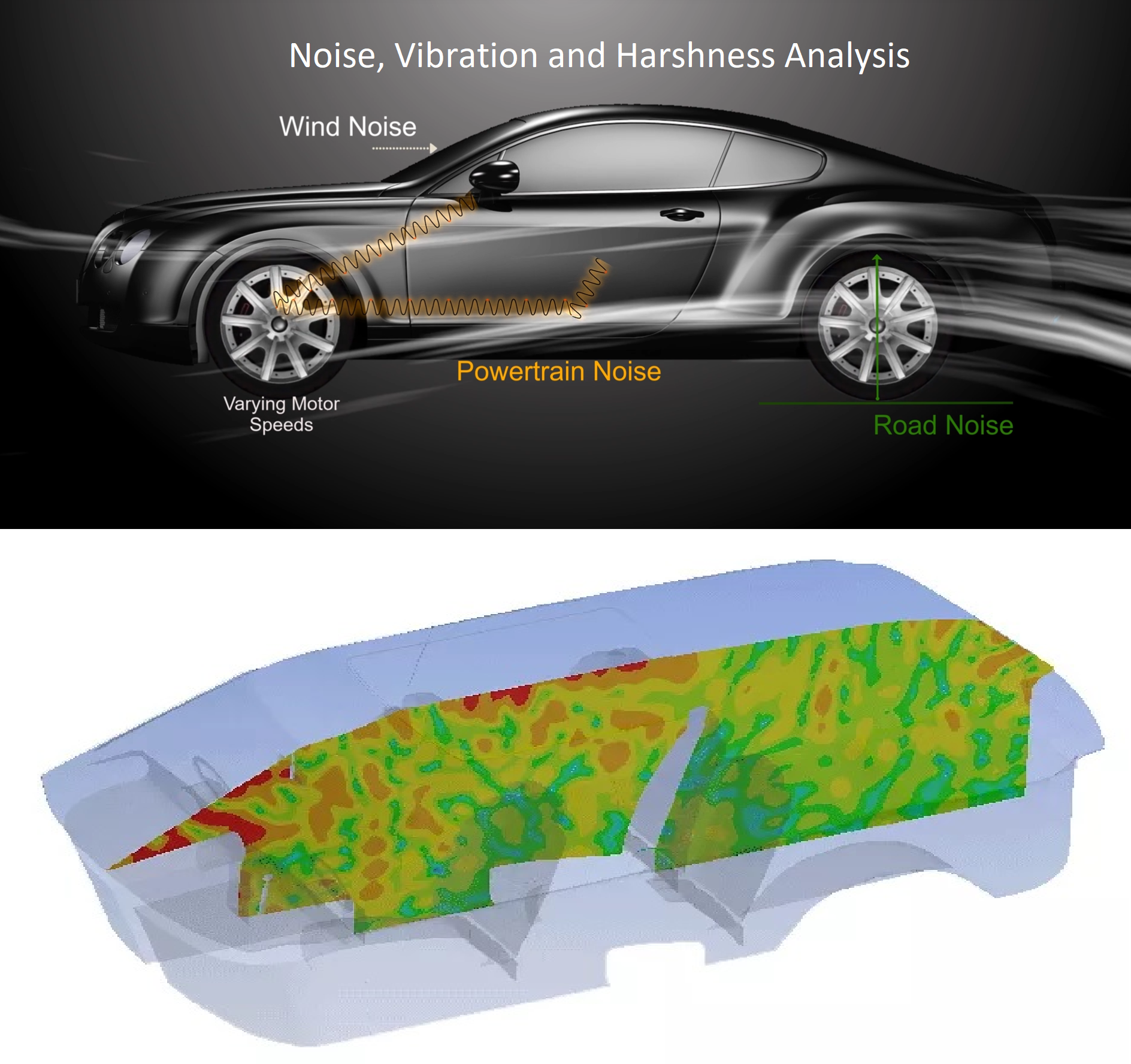

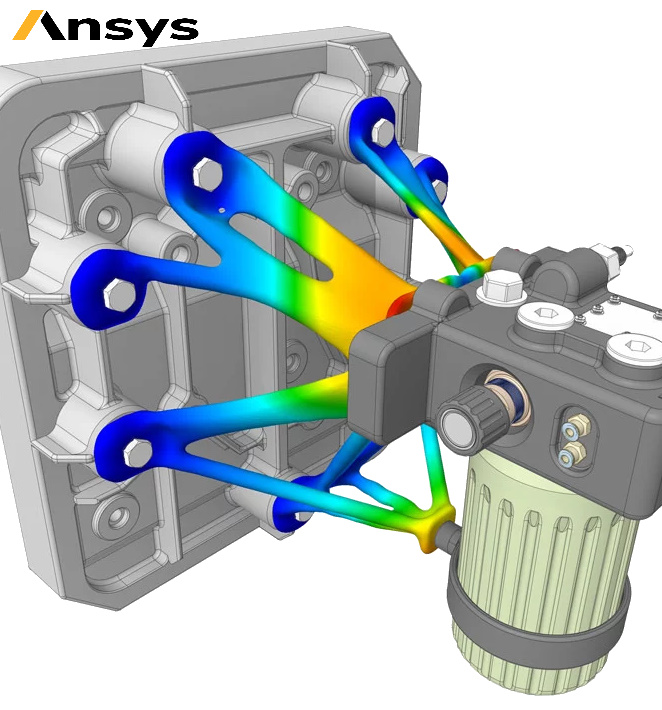

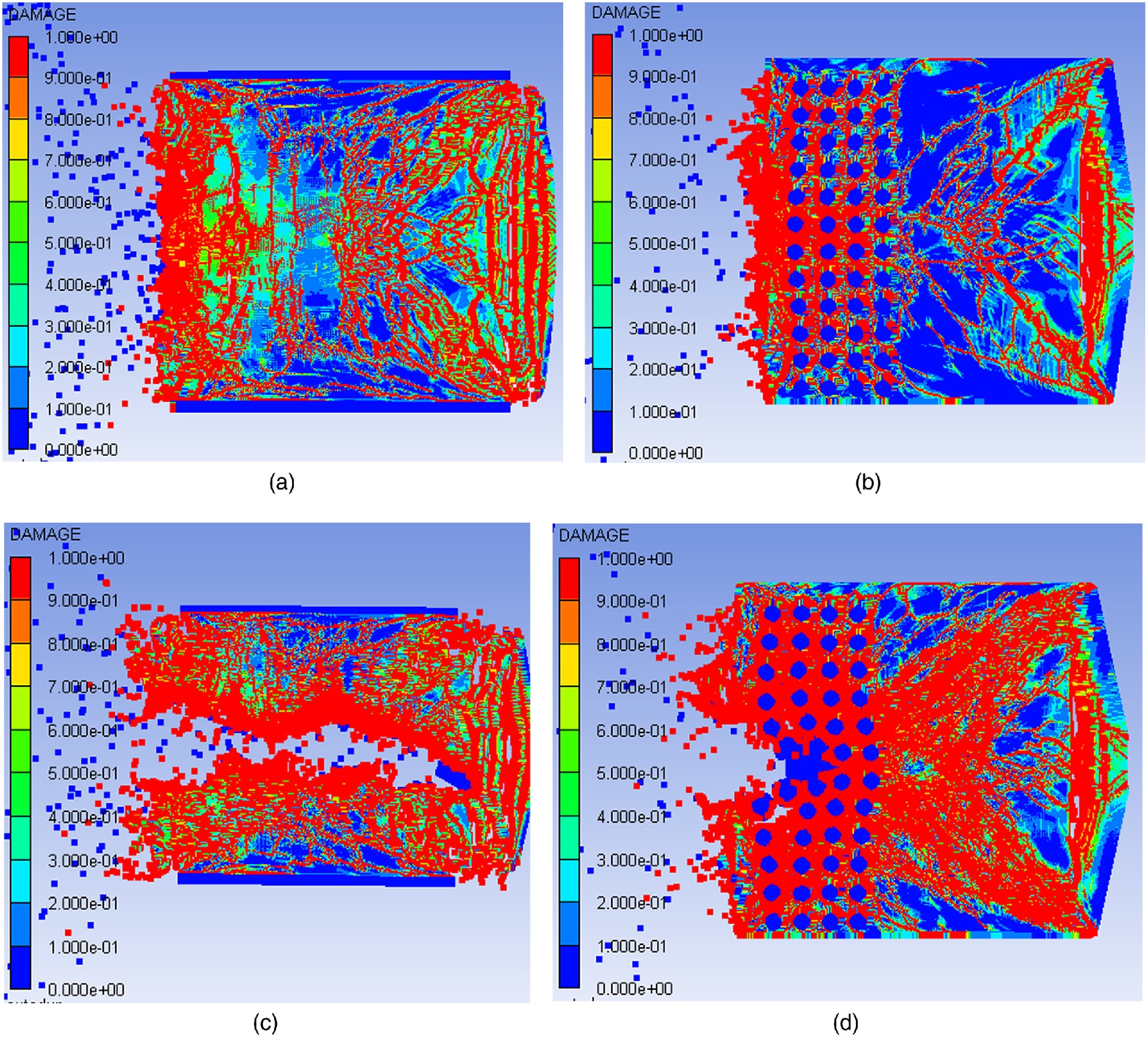

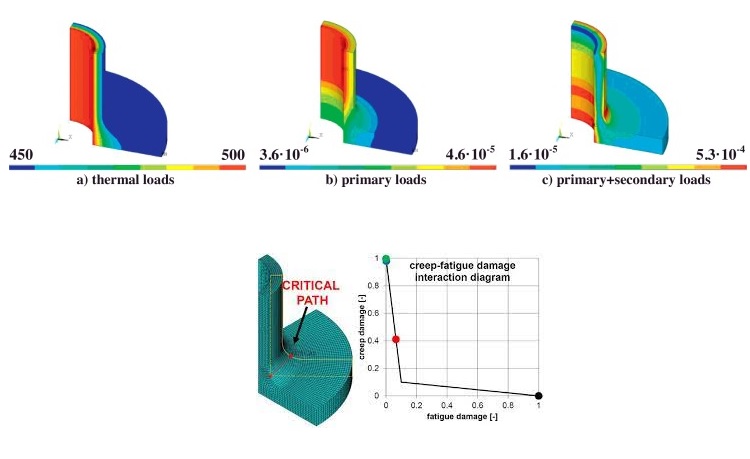

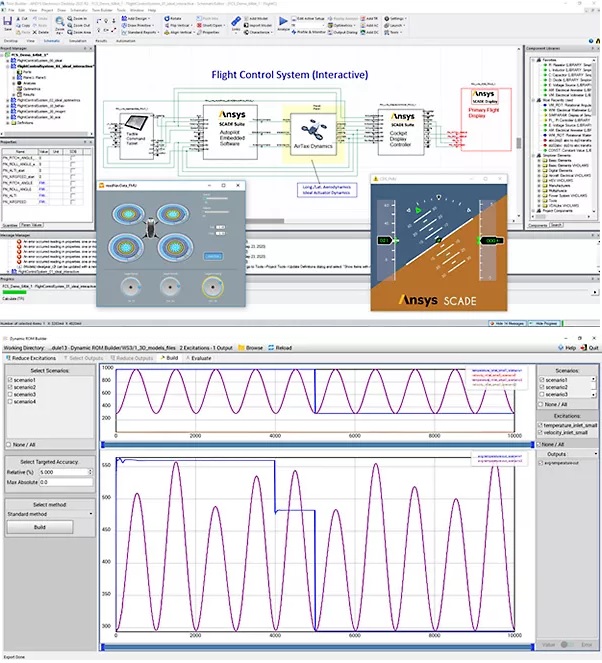

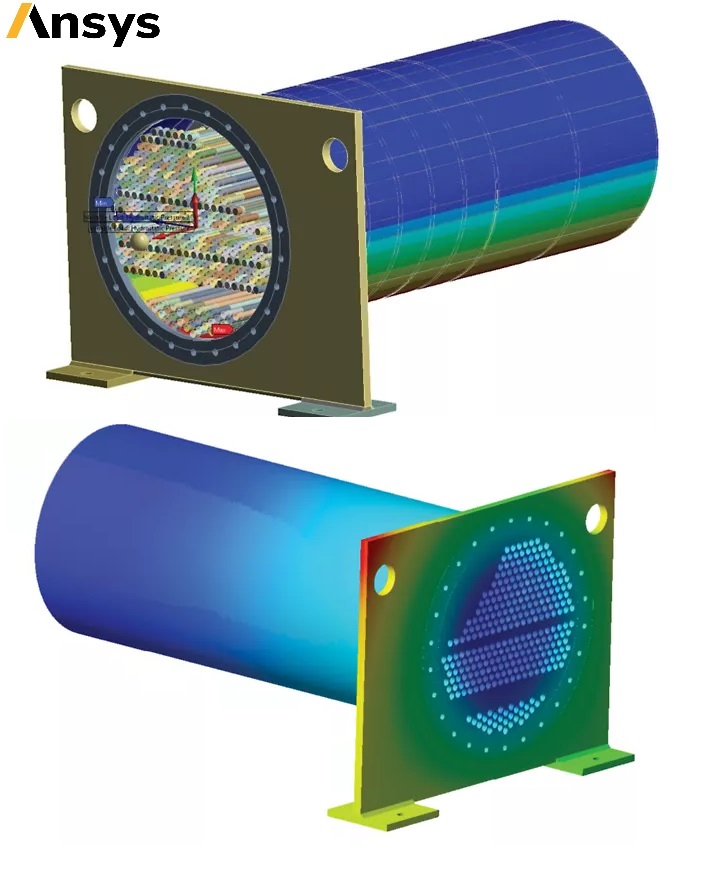

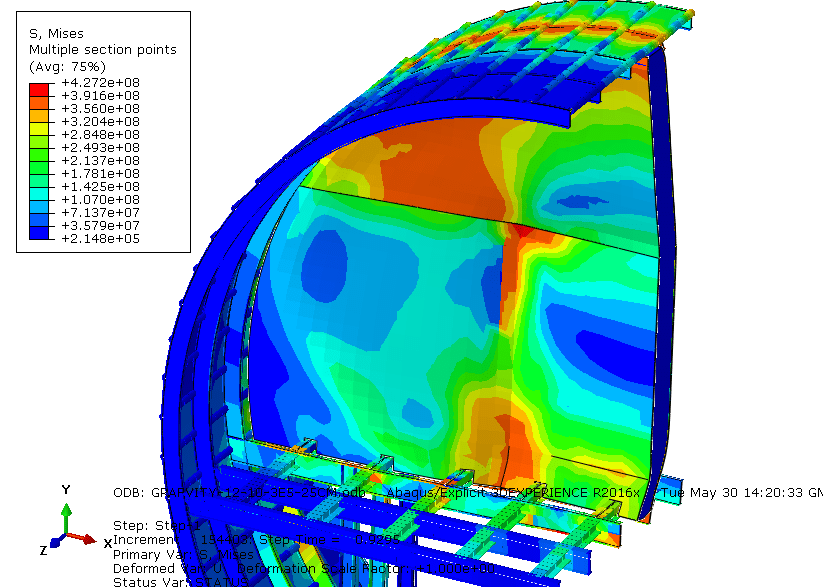

Hot forging is a highly specialized manufacturing process that requires careful control of temperature, pressure, and forming time to ensure high-quality parts with the desired mechanical properties. Finite element simulation with Ansys, LS-Dyna and Simulia Abaqus can be used to model and optimize the hot forging process, allowing engineers to predict and control the behavior of the material during forming.